Jute, often called the “golden fiber, is a natural, biodegradable crop widely used for sacks, ropes, carpets, and geo-textiles. Its low environmental footprint is increasingly valued, with global production hovering around 2.7 million tonnes annually. While India and Bangladesh dominate, supplying nearly 99% of the world’s output, jute cultivation also occurs in countries such as China, Uzbekistan, Nepal, and several in Africa and Latin America.

Jute Production Around The Globe

A thorough country-level examination of jute cultivation is essential for understanding the global jute landscape:

1. Production Shares and Volumes

-

In 2023, Bangladesh held a 50.38% share of global jute production, followed by India at 48.38%, accounting for nearly 99% of the output.

-

Other significant producers include China (0.51%), Uzbekistan (0.38%), Nepal (0.26%), South Sudan (0.10%), and Zimbabwe (0.082%).

-

India produces approximately 1.97 million tonnes annually, while Bangladesh yields around 1.24 million tonnes.

2. Crop Yield and Land Use

-

Total world production stands near 2.7 million tonnes, down from a high of about 4.5 million tonnes in 1985.

-

Declines in jute cultivation area in Bangladesh, over 25,000 hectares lost in a single year, have led to a 10.8% production drop in 2021–22.

3. Global Distribution Patterns

-

Over 80% of global jute production originates from the Ganges Delta, shared by Bangladesh and India.

-

The top three producing countries (India, Bangladesh, China) contribute around 98.9% of the total jute output.

4. Trade and Export Figures

-

Bangladesh exports about 0.6–0.8 million bales (out of 7–8 million produced annually) of raw jute.

-

Jute goods exports by Bangladesh totaled approximately USD 800 million in a recent year.

5. Trends and Shifts

-

In 2023, Bangladesh grew production by +2.08%, India declined by −0.60%, and China fell by −12.35% year‑on‑year.

-

Several smaller producers—South Sudan, Zimbabwe, Egypt—registered modest growth (+0.83%, +1.05%, −0.32% respectively).

What Is Jute and Why Is It Important Globally?

Jute is a long, soft, shiny bast fiber obtained from the plants Corchorus olitorius and Corchorus capsularis, grown mainly in warm, humid regions with alluvial soil. It is spun into coarse, strong threads and is among the most affordable natural fibers after cotton. Jute is biodegradable, compostable, and renewable, making it increasingly valuable in today’s environmentally conscious world.

Economic and Ecological Benefits

Jute plays a significant role in the agricultural economies of countries like India and Bangladesh, employing millions of farmers and workers in rural areas. In India alone, more than 4 million people are directly or indirectly dependent on the jute industry. It is also a low-input crop, requiring minimal pesticides and fertilizers, which reduces farming costs and environmental risks.

From an ecological perspective, jute helps improve soil fertility and absorbs large quantities of CO₂. One hectare of jute plants can absorb up to 15 tons of carbon dioxide and release 11 tons of oxygen during their growing season. It also prevents soil erosion and acts as a natural barrier during floods in deltaic regions.

Applications: Textile, Packaging, Geo-textiles, and More

Traditionally, jute has been used for making sacks, ropes, and coarse fabrics. However, modern applications have expanded significantly. Today, jute is used in:

-

Textiles: blended with cotton and other fibers for eco-friendly clothing and home textiles

-

Packaging: as a replacement for plastic in bags and sacks

-

Geo-textiles: for erosion control, road construction, and riverbank stabilization

-

Home décor: carpets, rugs, curtains

-

Agriculture: biodegradable pots and mulching sheets

Growing Demand for Sustainable Natural Fibers

With rising concerns over plastic pollution and climate change, there is a growing global demand for sustainable alternatives. Jute, being renewable and eco-friendly, is positioned as a leading solution. The European Union and other environmentally focused markets have significantly increased their demand for jute-based products in packaging and textiles, further strengthening jute’s global importance.

Jute cultivation process, source: Sahapedia YouTube

Ideal Conditions for Jute Cultivation & Why India and Bangladesh Have a Head Start?

Jute is a tropical crop that grows best in hot and humid climates with consistent rainfall and fertile, well-drained soil. It requires specific environmental conditions for optimal yield and fiber quality:

1. Soil Type:

Jute thrives in alluvial loamy soils, rich in organic matter and nutrients. The soil should be well-drained yet moisture-retentive, with a pH between 6.0 and 7.5. Sandy or clay-heavy soils are less suitable due to poor water regulation.

2. Temperature and Humidity:

Ideal temperatures range from 24°C to 37°C, with relative humidity over 70%. These warm, moist conditions support fast vegetative growth and robust fiber formation.

3. Rainfall:

Jute needs 1500–2500 mm of rainfall annually, with consistent distribution over the growing season. While adequate water is necessary, standing water can harm seedlings, making drainage equally crucial.

4. Sowing and Harvest Timeline:

-

Sowing: March to May, depending on regional climate.

-

Harvesting: Around 100–120 days after sowing, typically July to September.

-

Post-harvest, the stalks are left for retting, a microbial process essential for fiber separation.

The Jute Protagonists: India and Bangladesh

1. Geographical Advantage:

Both countries are located in the Ganges-Brahmaputra delta, which offers ideal alluvial floodplains, abundant water bodies for retting, and highly fertile soils. This natural landscape provides a near-perfect ecosystem for jute cultivation.

2. Climate Suitability:

The monsoon patterns in these regions deliver exactly the kind of warm and humid climate that jute needs high rainfall during the growing season, with relatively stable temperatures year-round.

3. Historical Cultivation and Expertise:

Jute has been grown in these regions for centuries, making India and Bangladesh not just producers but centers of agronomic knowledge, labor availability, and processing infrastructure.

4. Scale and Infrastructure:

India and Bangladesh together produce more than 95% of the world’s raw jute. Their dominance is supported by mill networks, established export channels, and government-backed policies such as India’s Jute Packaging Materials Act and Bangladesh’s raw jute export incentives.

These combined natural, historical, and institutional advantages give India and Bangladesh a clear lead in global jute cultivation.

Why Other Countries Are Facing Challenges in Jute Cultivation?

While India and Bangladesh dominate global jute production, several other countries have attempted to enter or expand in the jute sector. However, most face significant challenges that hinder large-scale or profitable cultivation. These obstacles are a combination of climatic limitations, infrastructure deficits, and economic or policy-related barriers.

1. Unsuitable or Inconsistent Climate

Jute requires specific agro-climatic conditions: high temperatures, heavy rainfall, and high humidity for extended periods. Many countries, such as Egypt, South Sudan, and regions in Latin America, have only partial suitability. Either rainfall is irregular, temperatures are too extreme, or the required humidity is lacking, leading to low yields or poor fiber quality.

2. Lack of Retting Facilities and Water Bodies

Jute is a crucial post-harvest process that requires plentiful, clean, slow-flowing water. Countries without adequate water infrastructure or access to suitable rivers and ponds find it difficult to perform effective retting, resulting in coarse, low-grade fiber. In many African and Central American regions, water scarcity or pollution further complicates this process.

3. Limited Technical Know-How

Unlike India or Bangladesh, newer jute-producing countries often lack experienced farmers, research institutions, or technical training programs. Without proper knowledge of crop cycles, pest management, and retting methods, the quality and consistency of the output suffer.

4. Inadequate Policy Support and Investment

In most jute-developing nations, governments prioritize staple food crops or export-oriented cash crops (like cotton, coffee, or soy). Jute receives little to no subsidy, insurance, or infrastructure support, making it a financially risky crop for farmers.

5. Labor and Market Access Issues

Jute farming is labor-intensive, especially during retting and fiber extraction. In countries with high labor costs or urban migration trends, there’s a shortage of rural workers. Additionally, limited processing units and domestic demand mean many farmers struggle to find buyers or export avenues.

These factors explain why many nations, even those with similar climates, struggle to scale jute cultivation effectively. Without the combined presence of natural resources, skilled labor, water access, and policy backing, jute cannot compete with better-supported crops or more dominant producers.

Country-Wise Jute Cultivation Analysis

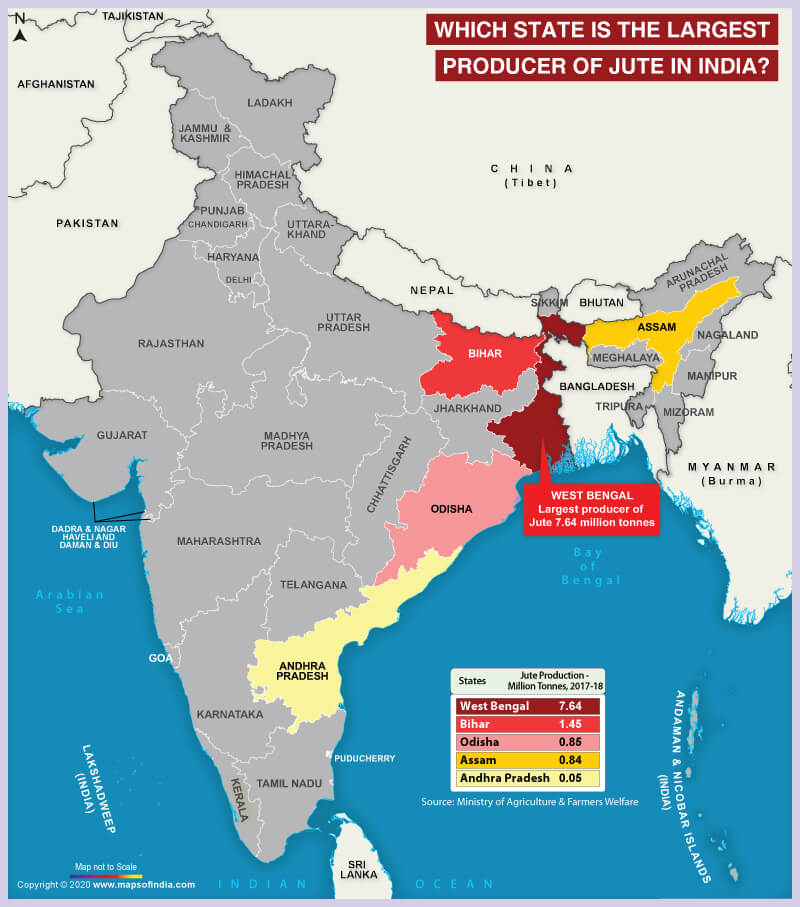

India – The Largest Jute Producer

Key Production Regions: West Bengal, Assam, Bihar, and Odisha

India accounts for approximately 60% of the world’s raw jute production. Among Indian states, West Bengal alone produces over 75% of the country’s total jute output. The major districts include Nadia, Murshidabad, Cooch Behar, and North 24 Parganas.

Assam contributes around 8 to 10%, primarily from the Brahmaputra Valley. Bihar produces nearly 10 to 12%, with districts like Katihar and Purnea being prominent. Odisha, though smaller in contribution, has been expanding its cultivation steadily.

Farming Practices and Technologies Used

Indian jute farming traditionally involves manual sowing between March and May and harvesting after 100 to 120 days. After harvesting, jute stalks undergo retting, a microbial process done in still or slow-moving water, which takes 10 to 15 days. This step is crucial for fiber quality but often compromised due to water shortages or poor retting techniques.

To address this, the government introduced Jute-ICARE (Improved Cultivation and Advanced Retting Exercise), promoting:

-

Certified high-yielding seeds

-

Microbial retting solutions

-

Soil testing and line sowing techniques

The adoption of these technologies has helped increase yield by up to 15 to 20% and improve fiber grades.

India produced about 1.24 million metric tonnes of raw jute in FY 2022–23. Approximately 85 to 90% of this is consumed domestically, driven largely by the Jute Packaging Materials Act, which mandates the compulsory use of jute for 100% of food grain packaging and 20% of sugar packaging. This legislation alone ensures a strong base demand for jute within India.

India exported nearly 14% of its raw jute production, amounting to around 177,270 metric tonnes. The total value of jute goods exports stood at approximately USD 471.8 million, with diversified jute products accounting for USD 160.4 million. Major export items include:

-

Jute yarn and twine

-

Hessian and sacking fabrics

-

Shopping bags and floor coverings

A significant portion of this export growth is attributed to the rise of jute bag manufacturers in India, particularly in states like West Bengal and Assam. These manufacturers are tapping into the global demand for reusable, biodegradable alternatives to plastic bags. They produce a wide range of bags, from plain grocery totes to custom-designed, high-end fashion accessories, catering to eco-conscious markets abroad.

Top export destinations for Indian jute goods include the USA, UK, Germany, France, Australia, Japan, and Egypt, with sustained interest from both wholesale buyers and sustainable fashion brands.

Government Support Schemes

The Indian government supports the jute sector through multiple schemes:

-

Minimum Support Price (MSP): Fixed at ₹4,750 per quintal in 2022–23, ensuring farmers receive fair returns.

-

Jute-ICARE: Helps over 2.5 lakh farmers with sustainable practices and retting improvements.

-

National Jute Development Program (NJDP): Provides capital subsidies for mill modernization.

-

Export Promotion Schemes: Includes Market Development Assistance and financial support for participation in trade fairs.

-

e-Governance (Jute SMART): Streamlines procurement and mill operations.

Challenges in the Indian Jute Industry

Despite its dominance, the Indian jute industry faces several issues:

-

Dependence on outdated machinery leads to low productivity in many mills.

-

Procurement inefficiencies often reduce the impact of MSP, especially due to middlemen.

-

Labor shortages caused by rural-to-urban migration impact harvesting and retting.

-

Climatic challenges like floods and cyclones affect both yield and quality.

-

Competition from synthetic substitutes still impacts demand for conventional jute sacks.

India remains the global leader in jute cultivation due to its climatic advantage, historical expertise, and strong policy backing. However, modernization, labor management, and climate adaptation remain critical for the sector’s future.

The Bangladesh Scenario –

Importance in Bangladesh’s Economy

Bangladesh ranks as the second-largest jute producer globally, responsible for about 30–35% of worldwide output. Annual production has hovered around 1.1–1.6 million tonnes, with domestic processing consuming over 1.16 million tonnes and earning approximately 3% of the nation’s export revenue and GDP.

The jute industry supports 10% of the workforce, spanning farming, processing, milling, and diversified product manufacturing. More than 220 private mills and roughly 25 state-owned mills contribute to local processing, along with around 700 diversified jute product manufacturers employing about 50,000 to 100,000 people.

Major Jute-Growing Areas: Khulna, Jessore, Faridpur

Key growing regions include Khulna, Jessore, and Faridpur.

-

Khulna Division, especially areas like Daulatpur, Paikgasa, Dumuria, Tala, and Mollahat, forms the heart of Bangladesh’s jute belt.

In the 2023–24 fiscal year, 834,674 bales of raw jute were exported from Khulna markets alone. -

Districts such as Faridpur, Jessore, and Gopalganj also contribute significantly to production.

Traditional vs Modern Practices

Bangladesh combines age-old cultivation and retting methods with evolving modern techniques. Traditional water body retting remains widespread due to the abundance of over 200 rivers, enabling natural fiber extraction.

Recent advancements include:

-

Genome sequencing of jute (2010) to improve quality.

-

Use of high-yield varieties, such as BJRI-9, offering up to 80 maunds per hectare compared to 65 from older types.

-

Expansion of mechanized retting tanks developed by the Bangladesh Jute Research Institute and supported by the Jute Diversification Promotion Centre.

-

However, many mills still rely on outdated equipment, leading to process inefficiencies .

Jute Mills & Value‑Added Products

Bangladesh supports around 220 to 245 private mills, plus roughly 25 public mills under privatization. The Bangladesh Jute Diversification Promotion Centre has introduced 282 diversified jute product categories, including home décor, automotive materials, and biodegradable composites.

Value-added product segments include:

-

Jute yarn and twine, hessian and sacking fabrics, shopping bags, carpets, geo‑textiles, automobile parts, jute charcoal sticks, and interior materials (e.g., dashboards).

-

Local innovators like the Bangladesh Jute Research Institute and BJMC have pioneered products like Sonali biodegradable jute bags and jute‑plastic composites, mixing up to 30% jute with plastic.

Export Destinations

Bangladeshi jute and jute goods reach over 100 countries, including Australia, Belgium, Brazil, China, Germany, India, Pakistan, UK, USA, UAE, Vietnam, and Russia.

In fiscal year 2022–23:

-

Total export receipts reached USD 912 million, with USD 500 million derived from yarn and twine.

-

Jute sacks and bags earned USD 109 million, while raw jute exports fetched USD 204 million.

-

Despite overall export declines—down 6% to USD 925 million in FY 2023–24—interest in jute escalates globally due to plastic bans and environmental policies.

Bangladesh’s jute sector displays robust strengths—natural endowments, skilled labor, research capabilities, and policy incentives. Still, it faces obstacles such as outdated mill machinery, export incentive delays, and competition from synthetic fibers. Continued modernization, diversification, and global market expansion will be essential for sustaining its global lead.

Other Countries

Beyond India and Bangladesh, several countries play smaller yet strategic roles in jute cultivation. Nepal produces around 10,000 tonnes annually, with over 70% of raw jute imported and nearly 95% of processed goods exported to India, though declining acreage and irrigation issues hinder its growth.

China, while not a major cultivator (around 30,750 tonnes in 2022), is a significant importer and processor, with thousands of active jute importers and rising demand in industrial packaging and eco-textiles.

Thailand’s production has dropped to around 26 tonnes annually, mainly serving local craft industries, while Myanmar sustains modest jute activity through state-backed mills like Okkyin, focusing on domestic consumption with emerging export interest.

In Africa, countries like Kenya, Sudan, and Uganda are running pilot jute programs, with climate conditions suitable but constrained by inadequate retting facilities and poor logistics infrastructure.

Latin America, particularly Brazil, maintains around 17,000 hectares of jute under cultivation near the Amazon basin, with yields of about 1.6 tonnes per hectare, mostly serving local packaging needs. Across these regions, limited infrastructure, low investment, and lack of organized export chains restrict global competitiveness, though sustainability trends and policy shifts present future growth opportunities.

Future Of Jute and Its People: Modern Machinery, Future Fashion Trends, Eco-Friendly Awareness

The future of jute and its cultivators hinges on a blend of modernization, sustainability, and global demand shifts. As eco-consciousness rises worldwide, jute is gaining recognition as a biodegradable, renewable alternative to plastics and synthetic fibers. This demand, however, must be matched with support at the grassroots, where most jute farmers still rely on age-old manual techniques.

Investment in modern retting technologies, improved seed varieties, and decentralized processing units could increase both quality and farmer incomes. Simultaneously, the global fashion and packaging industries are beginning to embrace jute for its rustic aesthetics and environmental appeal, leading to innovative products such as jute sneakers, handbags, and geotextiles.

Countries willing to modernize jute supply chains while ensuring fair pricing, training, and credit support to their cultivators will likely emerge as leaders in this sustainable fiber economy. The true future of jute will not only be written in export graphs but also in the lives of the millions who grow, process, and depend on it. If nurtured right, jute can become a flagship material in the next era of ethical fashion, circular economies, and climate-resilient agriculture.

Our Verdict

Jute stands at a unique crossroads, rooted in tradition yet full of potential for the future. As the world shifts toward sustainable choices, jute offers more than just a fiber; it represents a livelihood for millions, a solution to plastic pollution, and a bridge between rural economies and global green markets. For countries that invest in education, innovation, and equitable supply chains, jute can become a symbol of both economic resilience and environmental responsibility. This transformation is already visible through the rise of jute bag manufacturers, who are meeting global demand for eco-friendly alternatives while supporting local artisans and farmers.

The path ahead requires collaboration among farmers, governments, industries, manufacturers, and consumers. If embraced fully, the humble jute plant could lead a global movement toward a cleaner, fairer, and more sustainable future.

Great platform for finding AI tools! As someone who values efficiency and security, AIGO Tools simplifies the search for reliable solutions. Their AI Checker Essay tool is a smart addition for content verification. Keep up the good work!

Trying out scratch cards is a fun way to mix luck and strategy. If you’re into gaming platforms that offer more than just slots, check out the Jili777 app for a fresh take on digital play.

8wk7bu

Solid article! Thinking about bankroll management & variance is key in any tournament. JL Boss seems to offer a streamlined experience – easy access is huge! Check out boss jili for a quick start if you’re looking for new platforms to play on.

Interesting read! Understanding player psychology is key, especially in evolving markets like Vietnam. Platforms like 68wim login seem to be adapting well to local preferences with localized options & games. Good insights here!

That’s a fascinating take on recent race results! Seeing new players enter the scene is exciting – reminds me of joining phl win games and discovering all the options! Easy to get started, too. 😉

It’s smart to prioritize security when choosing an online casino – verifying accounts is crucial! Platforms like phlboss online casino seem to understand that, offering a smooth, secure experience with local payment options too. Fun & safe-a good combo!

RTP analysis is fascinating – seeing how platforms like 33wim link prioritize a smooth, localized experience for Vietnamese players is smart. Easy registration & funding are key to retention, right? Great stuff!

0jsl3a

ji3hwy

That’s a fascinating point about how tech is reshaping entertainment! Seeing platforms like 999phl com prioritize speed & security with AI & biometrics is genuinely impressive. It’s about the experience, right? Makes you think about future gaming!

It’s so important to remember gambling should be fun, not a source of stress. Seeing platforms like BossJL prioritize quick verification & easy deposits (check out bossjl download) is a good sign – responsible gaming starts with smooth, secure access! Let’s all play smart.

Online casinos like Super PH offer fun, but players must stay vigilant. Always check security features and use trusted platforms with clear withdrawal policies. Play smart, stay safe.

Solid article! Thinking about bankroll management & game selection is key, especially with platforms like jl boss app offering so many options. Security via KYC is a huge plus too! 👍

rsfu8q

t5bpsn

Great article! The focus on user experience really resonates – a smooth platform is key. Thinking about options like jljl555 link, seamless registration & security seem vital for trust. Enjoyable read, thanks for sharing!

Interesting read! Understanding player psychology is key, much like navigating a platform like uu 88 – assessing risks & rewards is crucial for success in any game. It’s all about calculated moves!

0ttzk5

It’s fascinating how easily online casinos like j8ph club tap into our reward systems! The KYC process-while necessary-feels like an extra hurdle, impacting initial engagement. Understanding those psychological triggers is key to responsible play.

Your network, your earnings—apply to our affiliate program now! https://shorturl.fm/ZWode

Promote our brand, reap the rewards—apply to our affiliate program today! https://shorturl.fm/D04zX

Join our affiliate program today and earn generous commissions! https://shorturl.fm/1DhWT

Sign up and turn your connections into cash—join our affiliate program! https://shorturl.fm/qBY3Q

s5giv5

Boost your income—enroll in our affiliate program today! https://shorturl.fm/Gat1C

Share our products and watch your earnings grow—join our affiliate program! https://shorturl.fm/gnSo4

rc6dkm

Roulette’s allure is truly in understanding probability – fascinating how RNGs underpin fair play! Platforms like 2jl app prioritize that, with robust KYC for secure gaming. It’s good to see responsible practices evolving in the Philippines market.

Earn recurring commissions with each referral—enroll today! https://shorturl.fm/t5lRR

Start earning on autopilot—become our affiliate partner! https://shorturl.fm/FwOUa

ndd6ge

Tap into a new revenue stream—become an affiliate partner! https://shorturl.fm/1BqVC

Earn passive income this month—become an affiliate partner and get paid! https://shorturl.fm/z4noy

Boost your income effortlessly—join our affiliate network now! https://shorturl.fm/Csvlf

Drive sales and watch your affiliate earnings soar! https://shorturl.fm/ckmN7

Your network, your earnings—apply to our affiliate program now! https://shorturl.fm/B6gp5

Share our products and watch your earnings grow—join our affiliate program! https://shorturl.fm/y6uuR

Smart bankroll management is key, regardless of the platform. Seeing platforms like Phlwim prioritize KYC for a phlwim login is a good sign-legitimacy matters! Always analyze before you play, though. It’s easy to get carried away.

Start earning passive income—join our affiliate network today! https://shorturl.fm/SZl4M

a570u3

Share our offers and watch your wallet grow—become an affiliate! https://shorturl.fm/FWwes

Earn passive income with every click—sign up today! https://shorturl.fm/slcb7

Interesting points! Responsible gaming & robust KYC are vital, as seen with platforms like winph99 link. Ensuring legitimacy & a secure experience builds trust for players – crucial in this evolving space. Good read!

Promote our brand, reap the rewards—apply to our affiliate program today! https://shorturl.fm/uhmbw

Drive sales and watch your affiliate earnings soar! https://shorturl.fm/MZGKV

Earn passive income this month—become an affiliate partner and get paid! https://shorturl.fm/onX2z

Start earning passive income—become our affiliate partner! https://shorturl.fm/ZdJHx

Share our link, earn real money—signup for our affiliate program! https://shorturl.fm/JExEr

Turn traffic into cash—apply to our affiliate program today! https://shorturl.fm/7HSLy

Start sharing our link and start earning today! https://shorturl.fm/DYpAo

Join our affiliate program and start earning commissions today—sign up now! https://shorturl.fm/bKtII

Start sharing our link and start earning today! https://shorturl.fm/DQotO

Partner with us for generous payouts—sign up today! https://shorturl.fm/iL7DP

Start profiting from your traffic—sign up today! https://shorturl.fm/pWZ7j

Turn your traffic into cash—join our affiliate program! https://shorturl.fm/Tg6mv

Your network, your earnings—apply to our affiliate program now! https://shorturl.fm/622wQ

Promote our brand and get paid—enroll in our affiliate program! https://shorturl.fm/k3YgA

Promote our products—get paid for every sale you generate! https://shorturl.fm/221q4

Особой популярностью пользуется раздел с рецептами для детского питания. Молодые мамы отмечают безопасность предложенных блюд и советы по оформлению, которые нравятся детям.

krasunindim.biz

Partner with us for high-paying affiliate deals—join now! https://shorturl.fm/0rP22

qh4lhu

Maximize your earnings with top-tier offers—apply now! https://shorturl.fm/6bYmF

Monetize your traffic with our affiliate program—sign up now! https://shorturl.fm/HHSpr

Start earning on every sale—become our affiliate partner today! https://shorturl.fm/bbhoh

Start earning instantly—become our affiliate and earn on every sale! https://shorturl.fm/Hfswz

Refer friends, collect commissions—sign up now! https://shorturl.fm/Wkz8Q

Share our offers and watch your wallet grow—become an affiliate! https://shorturl.fm/orZ2L

amj5ef

Be rewarded for every click—join our affiliate program today! https://shorturl.fm/JhFz7

Start earning passive income—become our affiliate partner! https://shorturl.fm/4v1qF

3u58sy

Sign up and turn your connections into cash—join our affiliate program! https://shorturl.fm/IUgbT

Grow your income stream—apply to our affiliate program today! https://shorturl.fm/lgc4D

Promote our products—get paid for every sale you generate! https://shorturl.fm/49gZV

Start earning on every sale—become our affiliate partner today! https://shorturl.fm/5OtG6

Unlock top-tier commissions—become our affiliate partner now! https://shorturl.fm/J8A6M

Unlock top-tier commissions—become our affiliate partner now! https://shorturl.fm/J8A6M

Your audience, your profits—become an affiliate today! https://shorturl.fm/N6GMX

Share our products, reap the rewards—apply to our affiliate program! https://shorturl.fm/JoIoY

Refer friends and colleagues—get paid for every signup! https://shorturl.fm/Q535n

Get started instantly—earn on every referral you make! https://shorturl.fm/rX2Wr

Refer and earn up to 50% commission—join now! https://shorturl.fm/o2DUO

Partner with us for high-paying affiliate deals—join now! https://shorturl.fm/Gb7lD

Mỗi lần vào blog là lại lượm được vài bí kíp chơi slots hay ho. Gần đây cộng đồng đang tranh cãi gay gắt về việc có nên cấm auto spin. Rảnh là lại ghé qua fi88 casino, đúng là nơi để giải trí sau giờ làm việc, thắng cũng kha khá nhé. Theo nhà phát triển: ‘Chúng tôi đang tối ưu trải nghiệm quay hũ cho người Việt.’

Earn big by sharing our offers—become an affiliate today! https://shorturl.fm/9tC3c

https://shorturl.fm/YuI97

0lbqhb

https://shorturl.fm/GXKNk

https://shorturl.fm/Q7OOB

https://shorturl.fm/D1vBV

https://shorturl.fm/wYist

https://shorturl.fm/OkUy1

https://shorturl.fm/rnNYz

https://shorturl.fm/JGULl

https://shorturl.fm/J6RVB

https://shorturl.fm/VdUD3

https://shorturl.fm/eACfZ

https://shorturl.fm/BYjMP

https://shorturl.fm/uldjM

https://shorturl.fm/vofCf

https://shorturl.fm/ItxIR

https://shorturl.fm/AEg3D

https://shorturl.fm/i5ly7

https://shorturl.fm/x9k71

https://shorturl.fm/dRZZi

https://shorturl.fm/3rjhU

https://shorturl.fm/A9tYE

https://shorturl.fm/WiItr

https://shorturl.fm/CFLXD

https://shorturl.fm/bmVeo

https://shorturl.fm/gEup7

https://shorturl.fm/RhLgZ

https://shorturl.fm/ONlC3

https://shorturl.fm/toLAw

https://shorturl.fm/65nUy

https://shorturl.fm/qie8H

https://shorturl.fm/VRlIU

https://shorturl.fm/ldDzt

3blwbo

https://shorturl.fm/SdwcJ

https://shorturl.fm/Wx6Pj

https://shorturl.fm/diUVt

https://shorturl.fm/GZEt2

https://shorturl.fm/fLzjF

zcwt5s

https://shorturl.fm/i5ykh

https://shorturl.fm/cDZV6

https://shorturl.fm/pRAHl

Really interesting read! It’s smart to approach online gaming with a mindful attitude – focusing on enjoyment, not just winning. Checking for a 222ph app download & verifying the site seems like a great first step for a secure experience! 👍

https://shorturl.fm/0PVf5

Strategic play is key in online gaming, and data-driven platforms are changing the game! Seeing robust security like KYC is reassuring. Curious to explore more – checking out the jljl boss app download apk for a smoother experience. Good fund management is vital, too!

https://shorturl.fm/QUgFg

https://shorturl.fm/SnVvH

https://shorturl.fm/as4cZ

https://shorturl.fm/OEaEL

https://shorturl.fm/DuhvY

https://shorturl.fm/CsWxr

https://shorturl.fm/MKwRy

https://shorturl.fm/OxHN7

https://shorturl.fm/O16gG

https://shorturl.fm/pKCw7

https://shorturl.fm/yn52p

asx2ht

https://shorturl.fm/2rxQk

https://shorturl.fm/bRMek

https://shorturl.fm/TvOOv

https://shorturl.fm/KpdRX

https://shorturl.fm/HDMLx

https://shorturl.fm/iFQ0v

https://shorturl.fm/rqjci

https://shorturl.fm/G0AOR

https://shorturl.fm/DRFkD

https://shorturl.fm/H2OTy

https://shorturl.fm/pzWBK

https://shorturl.fm/hg43u

Pingback: prix de kamagra vs

Pingback: buy cheap androxal purchase in australia

Pingback: buying enclomiphene cost new zealand

Pingback: discount dutasteride non prescription online

Pingback: flexeril cyclobenzaprine in canada pharmacie

Pingback: order gabapentin buy japan

Pingback: No r x needed for purchasing fildena

https://shorturl.fm/3cQk1

https://shorturl.fm/S5GRa

jo40gz

Pingback: cheapest buy itraconazole generic ingredients

Pingback: cheapest buy avodart generic london

Pingback: how to buy staxyn usa sales

Pingback: how to order rifaximin cheap no prescription

https://shorturl.fm/gUKql

https://shorturl.fm/QRZiX

Pingback: buy xifaxan overnight delivery

Pingback: žádný předpis kamagra příští den

https://shorturl.fm/kGryr

517si8

https://shorturl.fm/swzBX

https://shorturl.fm/nnBx2

https://shorturl.fm/coU4r

Interesting points on maximizing returns! Seeing platforms like jljl88 link game really change the accessibility of these games is neat. Proper account setup & verification are key for a smooth experience, too!

https://shorturl.fm/lxxVd

https://shorturl.fm/0LjIg

https://shorturl.fm/e0TOI

https://shorturl.fm/M4EU2

https://shorturl.fm/gUjpC

https://shorturl.fm/SMVqL

https://shorturl.fm/zQBUD

https://shorturl.fm/LaFvC

https://shorturl.fm/grXUH

https://shorturl.fm/tq6fY

https://shorturl.fm/EpeT8

https://shorturl.fm/IHxk8

https://shorturl.fm/Dd9lz

https://shorturl.fm/ZMgJc

https://shorturl.fm/l9aVY

idxh5r

Interesting analysis! Seeing more regulated platforms like phspin game emerge is great for transparency. Secure KYC & instant deposits (like GCash!) seem key for a positive user experience, and builds trust. 🤔

https://shorturl.fm/CXvi1

https://shorturl.fm/VKshX

https://shorturl.fm/l4jqq

https://shorturl.fm/j430W

https://shorturl.fm/COCIP

agdulo

https://shorturl.fm/gPvDG

g7bo0p

lriamq

https://shorturl.fm/9tZNd

https://shorturl.fm/DBphS

https://shorturl.fm/pNX2C

https://shorturl.fm/C8BWz

https://shorturl.fm/ouYer

https://shorturl.fm/GQIO6

https://shorturl.fm/wQPvM

https://shorturl.fm/0ZIvh

https://shorturl.fm/rx9Oz

https://shorturl.fm/zklCg

https://shorturl.fm/vdiVQ

https://shorturl.fm/ObqgL

Interesting read! It’s cool to see platforms like BigBunny blending Filipino culture with modern gaming – a truly unique approach. Thinking of checking out the bigbunny app download and experiencing that cultural connection myself! Great insights here.

https://shorturl.fm/oJjfZ

https://shorturl.fm/0IQvo

https://shorturl.fm/8cX2P

https://shorturl.fm/nRI8o

https://shorturl.fm/t5F6X

https://shorturl.fm/O3wnn

https://shorturl.fm/KAg9c

https://shorturl.fm/k0JWt

https://shorturl.fm/aVkGj

bb9nwc

https://shorturl.fm/Qla30

https://shorturl.fm/LBA2Y

https://shorturl.fm/X1fbc

https://shorturl.fm/Eg0JR

https://shorturl.fm/4z8u8

https://shorturl.fm/Bbuz1

https://shorturl.fm/hNKgV

https://shorturl.fm/M35Et

https://shorturl.fm/1XPrh

https://shorturl.fm/JqIcX

https://shorturl.fm/msgBF

https://shorturl.fm/hKXkS

https://shorturl.fm/pqZ8j

https://shorturl.fm/7mGGw

Really enjoying learning about different slot mechanics! It’s cool how accessible online casinos are becoming, especially in the Philippines. Thinking of checking out 777ph slot games – secure login & local payment options sound great! 👍

Smart bankroll management is key with any online gaming, especially with so many options now! Seeing platforms like superph11 club cater specifically to the PH market with legit options is interesting-security is a big plus for players. Remember to play responsibly!

https://shorturl.fm/wWRFY

https://shorturl.fm/E51wO

https://shorturl.fm/dkkog

https://shorturl.fm/sIKUC

https://shorturl.fm/GBUuk

https://shorturl.fm/qPoX1

https://shorturl.fm/iHKdV

https://shorturl.fm/DAwlf

https://shorturl.fm/IAk2o

https://shorturl.fm/soK80

https://shorturl.fm/0bo6f

https://shorturl.fm/PLB7z

https://shorturl.fm/lhAVI

https://shorturl.fm/gfUdd

https://shorturl.fm/sOyrI

https://shorturl.fm/mDy3Q

https://shorturl.fm/75uOz

https://shorturl.fm/Faph1

https://shorturl.fm/4qy86

https://shorturl.fm/r5Wfv

https://shorturl.fm/bEwCT

https://shorturl.fm/ExW3L

https://shorturl.fm/zXoxu

https://shorturl.fm/Coh6a

https://shorturl.fm/2AifK

https://shorturl.fm/UutO6

https://shorturl.fm/hdMYT

https://shorturl.fm/6PnKR

https://shorturl.fm/fgf1x

https://shorturl.fm/l6Lrt

https://shorturl.fm/F06jC

uottyq

https://shorturl.fm/hsTtw

https://shorturl.fm/rU8au

qjrnh8

https://shorturl.fm/jN1S5

https://shorturl.fm/UUmOC

Dice games are such a fascinating blend of luck & strategy! Seeing platforms like lodi646 cater to local preferences with PHP & GCash is smart. Quick signup & security features are a huge plus too! 👍

https://shorturl.fm/Zga4I

https://shorturl.fm/rHsgo

https://shorturl.fm/MlAGX

https://shorturl.fm/kp6GZ

rjtycy

https://shorturl.fm/Qn5O5

https://shorturl.fm/xY3cW

https://shorturl.fm/1QHZq

https://shorturl.fm/PIQBo

I enjoyed reading this article. Thanks for sharing your insights.

https://shorturl.fm/EHUMc

https://shorturl.fm/doE1o

https://shorturl.fm/9S5in

https://shorturl.fm/DsEoy

https://shorturl.fm/2PMO4

https://shorturl.fm/i8X0E

ygor9d

https://shorturl.fm/7juO9

https://shorturl.fm/YUuge

3ffd64

https://shorturl.fm/ymwSI

https://shorturl.fm/LbcGJ

https://shorturl.fm/8yWqQ

https://shorturl.fm/LTCgf

https://shorturl.fm/OISxp

https://shorturl.fm/ATM11

https://shorturl.fm/NbumT

https://shorturl.fm/TmZU0

https://shorturl.fm/QhAk8

https://shorturl.fm/HRxV5

https://shorturl.fm/r7Xfz

https://shorturl.fm/96Xnn

8idgsu

https://shorturl.fm/X8hQV

https://shorturl.fm/DnBfC

https://shorturl.fm/EhtzG

https://shorturl.fm/6SbYX

https://shorturl.fm/J2JQl

https://shorturl.fm/okC94

https://shorturl.fm/pFtWv

https://shorturl.fm/VvGBD

Looking for a guest post opportunity, if there is, please contact us

Buy the best hair oil here: Clickdeal.

https://learningtimesinfo.tech

Jute cultivation is a traditional work. Great

https://shorturl.fm/lxnON

https://shorturl.fm/wi6sb

https://shorturl.fm/bIdYN

https://shorturl.fm/6mX5t

https://shorturl.fm/spdaB

https://shorturl.fm/dfXoM

https://shorturl.fm/C2Vez

https://shorturl.fm/UDRaK

https://shorturl.fm/UU8cE

https://shorturl.fm/QkoKY

https://shorturl.fm/XrzRJ

https://shorturl.fm/HlyK5

https://shorturl.fm/Q7mua

https://shorturl.fm/LMzIs

https://shorturl.fm/G74SM

https://shorturl.fm/cI9cK

https://shorturl.fm/1T7Hb

https://shorturl.fm/5qSIe

https://shorturl.fm/kcvio

Really insightful article! It’s great to see platforms like legend link maya club prioritizing secure account creation & KYC – vital for responsible gaming & protecting players. Transparency is key! 👍

Fascinating to see how gaming regulations evolve! The Philippine approach, with PAGCOR oversight, is key for platforms like legend link maya online casino. Secure logins & KYC are vital for trust-a smart move for both players & operators!

https://shorturl.fm/qhP7k

https://shorturl.fm/oXMUS

https://shorturl.fm/CIHZG

https://shorturl.fm/bkkPb

lk7yxq

https://shorturl.fm/BZFaF

https://shorturl.fm/E6agd

https://shorturl.fm/j31zR

https://shorturl.fm/hOItQ

https://shorturl.fm/DGTvN

buy the best product here: Huda beauty

jute cultivation is not an easy task. thanks for working on this.

https://shorturl.fm/Qcnt8

aa0beg

https://shorturl.fm/gM31Q

https://shorturl.fm/uhKJ5

https://shorturl.fm/0rTtK

https://shorturl.fm/fuXPW

https://shorturl.fm/kBNhe

https://shorturl.fm/FMs1u

https://shorturl.fm/HgYAk

https://shorturl.fm/Rysy7

dldc6i

Really interesting read! I’m always curious about how platforms like jlph63 link cater to local preferences – the GCash & PayMaya integration sounds super convenient for Filipino players! It’s great to see secure options too. 👍

Interesting read! Seeing platforms like jlph63 slot really cater to local preferences-Peso transactions & GCash are key for Filipino players. Security & easy access are huge wins too! 👍

https://shorturl.fm/c6VTv

https://shorturl.fm/7xGwU

https://shorturl.fm/78Rn1

https://shorturl.fm/7aBvY

62a4c4

https://shorturl.fm/nTqwH

https://shorturl.fm/VcBZT

https://shorturl.fm/PGztJ

https://shorturl.fm/IxLoU

https://shorturl.fm/ycGgc

Interesting analysis! Seeing these patterns really makes you think about probability. Platforms like jl boss app casino are innovating with tech, but luck still plays a huge role, right? It’s a fascinating intersection of data & chance!

Interesting analysis! Seeing platforms like jl boss download apk really push tech boundaries in the Philippines-security & seamless play are key. It’s fascinating how gaming evolves! 🤔

https://shorturl.fm/OzwyR

https://shorturl.fm/YmU2t

https://shorturl.fm/G3kP4

https://shorturl.fm/evCyK

https://shorturl.fm/f0EDd

https://shorturl.fm/7m8xV

Solid article! Thinking about bankroll management & game selection is key for consistent wins. I’ve been checking out ph sky game – easy deposits with GCash are a huge plus for Filipino players! Definitely helps stay focused on strategy.

Baccarat strategy is fascinating – observing patterns can give you an edge, but discipline is key! Seeing platforms like ph sky vip prioritize responsible gaming & quick PHP deposits (GCash is a lifesaver!) is a great sign for players. 👍

https://shorturl.fm/iHjRY

https://shorturl.fm/dS0nY

https://shorturl.fm/iEsH4

https://shorturl.fm/A1ciw

https://shorturl.fm/g0pl7

https://shorturl.fm/lzRL2

https://shorturl.fm/lvD5R

https://shorturl.fm/0hYqr

https://shorturl.fm/hoaN1

https://shorturl.fm/4IFhD

https://shorturl.fm/AHDtw

https://shorturl.fm/NMHFz

https://shorturl.fm/boSYX

https://shorturl.fm/5TF9J

https://shorturl.fm/HFBry

https://shorturl.fm/Gcuz2

https://shorturl.fm/ZJnN8

https://shorturl.fm/oibJi

https://shorturl.fm/HT0dy

https://shorturl.fm/UHBgx

https://shorturl.fm/Od7bn

viu9q0

https://shorturl.fm/HCYL7

https://shorturl.fm/sanqH

https://shorturl.fm/WTWBG

https://shorturl.fm/cjKZP

https://shorturl.fm/kZ14p

https://shorturl.fm/CPIRd

https://shorturl.fm/pOIE7

https://shorturl.fm/y7YUM

https://shorturl.fm/8T59f

https://shorturl.fm/DUudb

https://shorturl.fm/VYThz

https://shorturl.fm/wAqhF

https://shorturl.fm/SPwXx

1fbm91

https://shorturl.fm/Zv4d1

https://shorturl.fm/oNY93

ay44dr

https://shorturl.fm/FLjw1

https://shorturl.fm/CCQFb

https://shorturl.fm/Gqnbn

https://shorturl.fm/v4vwg

https://shorturl.fm/OEp90

https://shorturl.fm/qZnAg

https://shorturl.fm/3dYAo

https://shorturl.fm/w1YAW

https://shorturl.fm/77JBG

https://shorturl.fm/WKGYJ

https://shorturl.fm/s0FsU

https://shorturl.fm/yNJuk

b90mn5

https://shorturl.fm/uZYdH

https://shorturl.fm/rglct

https://shorturl.fm/ARp5T

https://shorturl.fm/i7hcl

https://shorturl.fm/lyH4h

https://shorturl.fm/ApCwH

https://shorturl.fm/MYOJp

https://shorturl.fm/AAUFN

https://shorturl.fm/GDSna

https://shorturl.fm/lS5t0

https://shorturl.fm/FsRYZ

https://shorturl.fm/R2tOs

https://shorturl.fm/Yl3vI

https://shorturl.fm/R0vvy

https://shorturl.fm/uJ1qO

https://shorturl.fm/xgeok

https://shorturl.fm/fY4I4

https://shorturl.fm/yNuOo

https://shorturl.fm/aK6kF

https://shorturl.fm/7WpJc

https://shorturl.fm/axYeO

https://shorturl.fm/hdBnN

It’s great seeing platforms prioritize player well-being alongside entertainment! Setting limits & session alerts, like on kinggame app download apk, is so important. Responsible gaming is key for long-term enjoyment! ✨

Interesting analysis! Seeing more platforms prioritize responsible gaming is great – KingGame seems to be leading that charge. Easy deposit options like GCash are a huge plus! Check out the kinggame apk for a secure & fun experience. Solid insights on the match, though!

It’s fascinating how platforms like Jiliph blend AI with gaming to improve user experience. The psychology behind tailored gameplay is just as thrilling as the games themselves.

This breakdown hits all the right marks-strategic depth and fun execution. Platforms like Jili77 are raising the bar with AI-driven insights, making every session a learning curve and a thrill ride.

https://shorturl.fm/oNkf4

Really digging this article! Understanding card values – like in super ace deluxe demo – is key to any strategy. It’s cool how even beginners can pick up the basics quickly, building confidence at the table! Great read.

That’s a fascinating point about risk tolerance – crucial for any game of chance! Seeing how Super Ace balances accessibility with strategic depth-especially those golden card variants-is smart. Check out a super ace demo to see what I mean! It’s a unique approach.

https://shorturl.fm/InARm

https://shorturl.fm/ApbY5

https://shorturl.fm/g1uoO

https://shorturl.fm/gTaA9

https://shorturl.fm/gTaA9

https://shorturl.fm/0tYax

https://shorturl.fm/BGZ8I

https://shorturl.fm/PYDKM

https://shorturl.fm/EmhgX

https://shorturl.fm/YDB3G

https://shorturl.fm/Vmocz

https://shorturl.fm/8d0lV

https://shorturl.fm/FWw4H

https://shorturl.fm/3m5bF

https://shorturl.fm/G4GKa

https://shorturl.fm/Rrwxn

https://shorturl.fm/s27vS

https://shorturl.fm/aPPhk

https://shorturl.fm/UMHgF

https://shorturl.fm/6bIZU

https://shorturl.fm/u5D8U

https://shorturl.fm/cM7b1

https://t.me/s/pt1win/320

https://shorturl.fm/zirmJ

https://shorturl.fm/NgBro

https://shorturl.fm/xa0WH

https://shorturl.fm/RtdzX

https://shorturl.fm/roVYU

The admin panel sounds like a command center for digital heists, with real-time logs and Telegram pings that keep operators one step ahead of any fallout.

Victim Journey

Актуальные рейтинги лицензионных онлайн-казино по выплатам, бонусам, минимальным депозитам и крипте — без воды и купленной мишуры. Только площадки, которые проходят живой отбор по деньгам, условиям и опыту игроков.

Следить за обновлениями можно здесь: https://t.me/s/reitingcasino

https://shorturl.fm/BHZ9p

https://shorturl.fm/HTTNF

https://t.me/iGaming_live/4644

https://shorturl.fm/5eKqf

The panel’s payment processing keeps it all in-house, dodging external scrutiny.

TON Drainer

Templates for Binance mimic exchanges too well for comfort.

Quark Drainer

https://shorturl.fm/RVodx

https://shorturl.fm/n0mxi

https://shorturl.fm/GZXDT

https://shorturl.fm/bkg5L

https://t.me/s/iGaming_live/4637

kraken онлайн

https://kraken-shop24.com

https://shorturl.fm/XSXMM

https://shorturl.fm/zvf6G

https://t.me/reyting_topcazino/16

https://shorturl.fm/xQMdA

https://shorturl.fm/X1dHU

https://shorturl.fm/Jz8Ts

bpk2z9

https://shorturl.fm/Qqqna

https://shorturl.fm/nY1VX

https://t.me/s/reyting_topcazino/22

https://shorturl.fm/eyfdV

https://shorturl.fm/PzJ2Q

https://shorturl.fm/eZr6l

https://shorturl.fm/IFnUC

https://shorturl.fm/KoGT6

https://shorturl.fm/5hKrG

kraken tor

kraken онлайн

кракен сайт

кракен ссылка

https://shorturl.fm/A006U

kraken ios

кракен qr код

https://shorturl.fm/jQP61

кракен qr код

kraken vk6

https://shorturl.fm/wQ479

https://shorturl.fm/weRg6

kraken

кракен зеркало

kraken vk5

kraken вход

https://shorturl.fm/Cf1I2

кракен даркнет

kraken 2025

https://shorturl.fm/Vu6T4

https://shorturl.fm/mx37T

https://shorturl.fm/oik33

https://shorturl.fm/oPsm0

https://shorturl.fm/IZjoH

https://shorturl.fm/BEAsy

https://t.me/of_1xbet/744

https://shorturl.fm/j5rLv

https://shorturl.fm/1KnGH

Okay, so I was looking for a new sportsbook and 121bett popped up. The odds seem pretty competitive. Thinking of putting a few bets on the upcoming games. Anyone used them before? Share your thoughts! This is the link: 121bett

мега зеркало без капчи

мега Москва

mega тор работает стабильно

мега Россия

мега купить ссылку дайте нормальную

mega официальный сайт

mega даркнет ссылка свежая

mega onion

ссылка на мега без проблем

mega вход

адрес меги без тор

МЕГА ссылка

сайт mega рабочий на сейчас

мега onion

mega link рабочий пожалуйста

мега market

mega спб кто пользуется

MEGA 2

мега сайт не открывается что делать

мега как зайти

мега зеркало без капчи

мега магазин даркнет

https://shorturl.fm/ft0fn

https://shorturl.fm/hdCO5

https://t.me/s/ef_beef

https://shorturl.fm/vQPwt

https://shorturl.fm/4XU5W

https://shorturl.fm/YdAFE

https://shorturl.fm/ek2q9

https://shorturl.fm/crxsL

mega fo зеркало или нет

мега

mega link рабочий пожалуйста

мега маркет официальный сайт

https://shorturl.fm/iw8aT

https://shorturl.fm/io3nZ

https://shorturl.fm/2YQpL

https://shorturl.fm/K9wnC

https://shorturl.fm/GRiDf

https://shorturl.fm/h9AAw

https://shorturl.fm/acz2v

https://shorturl.fm/00fNU

https://shorturl.fm/at7sx

https://shorturl.fm/3kUvr

https://shorturl.fm/MnqOI

kraken вход

кракен официальный сайт

https://shorturl.fm/grdax

https://shorturl.fm/YFqWY

ігрові слоти ігрові слоти

That’s a fascinating take on longshot strategies! Seeing platforms like x777 live download apk offer easy access via app download makes tracking bets even smoother. Good analysis! 👍

https://shorturl.fm/egzTw

Okay people, trying out shahspingame. Not bad, has a few interesting things going for it. I’d say give it a quick spin! Check it at shahspingame

https://t.me/officials_pokerdom/3373

https://shorturl.fm/5aPpK

kraken

кракен онлайн

kraken официальный

площадка кракен

кракен даркнет маркет

кракен онион

kraken tor

кракен маркет даркнет тор

кракен даркнет маркет

кракен маркет даркнет тор

https://shorturl.fm/v7jGT

кракен ссылка

площадка кракен

kraken ссылка

kraken сайт

kraken ссылка

кракен даркнет

kraken tor

кракен онлайн

Krn

площадка кракен

kraken сайт

кракен маркет даркнет скачать

кракен онион

кракен маркет тор

кракен ссылка тор

Krn

ссылка на кракен

кракен маркетплейс

kraken darknet

кракен маркет тор

vk1

кракен ссылка тор

кракен актуальная ссылка

кракен маркет даркнет тор

кракен вход

kraken6 +at

кракен ссылка

кракен маркет тор

кракен маркет

как зайти на кракен

кракен зеркало

кракен маркет тор

кракен рабочая

кракен актуальная ссылка

https://shorturl.fm/AMWtl

кракен актуальная ссылка

2krn

https://shorturl.fm/WMWBX

Love how scratch cards blend luck and thrill! It’s fascinating how platforms like tyy.AI Tools simplify finding AI tools-especially the AI Ad Generator for creative campaigns. Innovation meets fun!

Blackjack strategy is fascinating – understanding when to hit or stand really changes the game! Seeing platforms like PH366 offer live casino options with easy deposits (GCash is great!) makes learning even more accessible. Check out a ph366 login legit guide to get started! It’s all about building confidence at the table.

https://shorturl.fm/2rX3a

Having a blast over at fun222! Lots of fast games, the slots are fun, and the bonuses keep things interesting. I’ve recommended it to me friends as well, try it out for yourself!: fun222

Interesting analysis! Seeing platforms like ph22 club slot prioritize quick registration & easy deposits (like GCash) is key for Filipino players. Accessibility really drives engagement, don’t you think? Good stuff!

https://shorturl.fm/kH3ms

That’s a fascinating take on longshot potential! Seeing how quickly content creation is evolving-tools like Veo 3.1 are game-changers. Accessibility across devices is key for analyzing data on the go, too!

https://t.me/s/Volna_officials

Колодцы под ключ https://kopkol.ru в Московской области — бурение, монтаж и обустройство водоснабжения с гарантией. Изготавливаем шахтные и бетонные колодцы любой глубины, под ключ — от проекта до сдачи воды. Работаем с кольцами ЖБИ, устанавливаем крышки, оголовки и насосное оборудование. Чистая вода на вашем участке без переплат и задержек.

Инженерные изыскания https://sever-geo.ru в Москве и Московской области для строительства жилых домов, коттеджей, коммерческих и промышленных объектов. Геология, геодезия, экология, обследование грунтов и оснований. Работаем по СП и ГОСТ, есть СРО и вся необходимая документация. Подготовим технический отчёт для проектирования и согласований. Выезд на объект в короткие сроки, прозрачная смета, сопровождение до сдачи проекта.

Доставка дизельного топлива https://ng-logistic.ru для строительных компаний, сельхозпредприятий, автопарков и промышленных объектов. Подберём удобный график поставок, рассчитаем объём и поможем оптимизировать затраты на топливо. Только проверенные поставщики, стабильное качество и точность дозировки. Заявка, согласование цены, подача машины — всё максимально просто и прозрачно.

Доставка торфа https://bio-grunt.ru и грунта по Москве и Московской области для дач, участков и ландшафтных работ. Плодородный грунт, торф для улучшения структуры почвы, готовые земляные смеси для газона и клумб. Быстрая подача машин, аккуратная выгрузка, помощь в расчёте объёма. Работаем с частными лицами и организациями, предоставляем документы. Сделайте почву на участке плодородной и готовой к посадкам.

Строительство домов https://никстрой.рф под ключ — от фундамента до чистовой отделки. Проектирование, согласования, подбор материалов, возведение коробки, кровля, инженерные коммуникации и внутренний ремонт. Работаем по договору, фиксируем смету, соблюдаем сроки и технологии. Поможем реализовать дом вашей мечты без стресса и переделок, с гарантией качества на все основные виды работ.

Геосинтетические материалы https://stsgeo.ru для строительства купить можно у нас с профессиональным подбором и поддержкой. Продукция для укрепления оснований, армирования дорожных одежд, защиты гидроизоляции и дренажа. Предлагаем геотекстиль разных плотностей, георешётки, геомембраны, композитные материалы.

Sprunki Incredibox truly shines by blending creativity with intuitive design-perfect for both novices and seasoned creators. Check out Sprunki Incredibox to experience the next level of musical play.

Доставка грузов https://avalon-transit.ru из Китая «под ключ» для бизнеса и интернет-магазинов. Авто-, ж/д-, морские и авиа-перевозки, консолидация на складах, проверка товара, страхование, растаможка и доставка до двери. Работаем с любыми партиями — от небольших отправок до контейнеров. Прозрачная стоимость, фотоотчёты, помощь в документах и сопровождение на всех этапах логистики из Китая.

That’s a great point about balancing accessibility with depth in shooting games! I’ve been checking out i8 club download apk and their streamlined registration is impressive – makes getting into new games so much easier. Good UX is key!

https://shorturl.fm/dkW66

https://shorturl.fm/EoHoV

новости беларуси сегодня новости беларуси 2025

Самое интересное по клику: бизнес-кредиты казахстан

Защищенный kraken сайт требует обязательного использования Tor браузера для доступа, блокируя попытки входа через обычные браузеры без анонимизации.

Актуальная kraken onion ссылка публикуется в официальных телеграм каналах с PGP верификацией подписи администрации для подтверждения подлинности адреса маркета.

Strona internetowa mostbet – zaklady sportowe, zaklady e-sportowe i sloty na jednym koncie. Wygodna aplikacja mobilna, promocje i cashback dla aktywnych graczy oraz roznorodne metody wplat i wyplat.

Хочешь айфон? смартфон apple iphone выгодное предложение на новый iPhone в Санкт-Петербурге. Интернет-магазин i4you готов предложить вам решение, которое удовлетворит самые взыскательные требования. В нашем каталоге представлена обширная коллекция оригинальных устройств Apple. Каждый смартфон сопровождается официальной гарантией производителя сроком от года и более, что подтверждает его подлинность и надёжность.

It’s fascinating how easily we fall into patterns when seeking entertainment! Seeing platforms like phparadise vip prioritize quick registration & easy deposits really taps into that desire for instant gratification. Understanding those psychological triggers is key, right? 🤔

Лучшее прямо здесь: https://medim-pro.ru/kupit-spravku-ot-ginekologa/

Оформление медицинских анализов https://medim-pro.ru и справок без очередей и лишней бюрократии. Запись в лицензированные клиники, сопровождение на всех этапах, помощь с документами. Экономим ваше время и сохраняем конфиденциальность.

https://shorturl.fm/0uLez

https://t.me/s/iGaming_live/4868

Downloading the ssbet77app now! Hope it’s not just another storage hog. Fingers crossed for easy betting and fast payouts! Salamat! Get the app here: ssbet77app

https://shorturl.fm/ib9XK

Free video chat visit website find people from all over the world in seconds. Anonymous, no registration or SMS required. A convenient alternative to Omegle: minimal settings, maximum live communication right in your browser, at home or on the go, without unnecessary ads.

https://shorturl.fm/oCr95

https://shorturl.fm/w0Oyt

https://shorturl.fm/bemAr

Recommended reading: https://buannelstudio.in/2025/10/08/akkaunty-facebook-google-instagram-tik-tok-26/

https://shorturl.fm/oSDas

Full version of the article: https://id.gta5-mods.com/users/puzzlefree

Ultimately, a music ai generator is a tool that expands the creative toolkit available to artists.

Интернет-магазин https://stsgeo-krd.ru геосинтетических материалов в Краснодар: геотекстиль, георешётки, геоматериалы для дорог, фундаментов и благоустройства. Профессиональная консультация и оперативная доставка.

Геосинтетические материалы https://stsgeo-spb.ru для строительства и благоустройства в Санкт-Петербурге и ЛО. Интернет-магазин геотекстиля, георешёток, геосеток и мембран. Работаем с частными и оптовыми заказами, быстро доставляем по региону.

Строительные геоматериалы https://stsgeo-ekb.ru в Екатеринбурге с доставкой: геотекстиль, объемные георешётки, геосетки, геомембраны. Интернет-магазин для дорожного строительства, ландшафта и дренажа. Консультации специалистов и оперативный расчет.

Криптографическая верификация показывает как проверить кракен ссылку через импорт официального PGP ключа в GPG и выполнение команды verify для подписанного сообщения с адресом.

Нужна работа в США? курс диспетчера грузоперевозок недорого : работа с заявками и рейсами, переговоры на английском, тайм-менеджмент и сервис. Подходит новичкам и тем, кто хочет выйти на рынок труда США и зарабатывать в долларах.

Нужна работа в США? цена курса диспетчера грузоперевозок в сша онлайн с трудоустройством : работа с заявками и рейсами, переговоры на английском, тайм-менеджмент и сервис. Подходит новичкам и тем, кто хочет выйти на рынок труда США и зарабатывать в долларах.

Uwielbiasz hazard? nv casino opinie: rzetelne oceny kasyn, weryfikacja licencji oraz wybor bonusow i promocji dla nowych i powracajacych graczy. Szczegolowe recenzje, porownanie warunkow i rekomendacje dotyczace odpowiedzialnej gry.

Срочный вызов электрика https://vash-elektrik24.ru на дом в Москве. Приедем в течение часа, быстро найдём и устраним неисправность, заменим розетки, автоматы, щиток. Круглосуточный выезд, гарантия на работы, прозрачные цены без скрытых доплат.

https://shorturl.fm/6AVrd

https://shorturl.fm/7g9lB

Details inside: https://kissnara.com/bbs/board.php?bo_table=free&wr_id=26

Heya this is kind of of off topic but I was wondering if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding expertise so I wanted to get guidance from someone with experience. Any help would be greatly appreciated!

directory of female escorts in Rio

https://pirots.win/

This is the harsh truth: the majority of HVAC failures happen because someone ignored a step. Didn’t calculate the load properly. Used undersized equipment. Miscalculated the insulation needs. We’ve fixed countless of these messes. And every time, we file away another insight. Like in 2017, when we decided on adding remote monitoring to each system. Why? Because Sarah, our senior tech, got sick of watching homeowners burn money on bad temperature settings. Now clients save 20-30% yearly.

https://www.bbb.org/us/wa/marysville/profile/refrigeration/product-air-heating-cooling-and-electrical-1296-1000154140

Ktobetbr, looking good for my Brazilian friends! I’ll give it a try and check the language options. Worth a shot. ktobetbr

This is the dirty truth: most septic companies just maintain tanks. They are like temporary salesmen at a demolition convention. But Septic Solutions? They are different. It all started back in the beginning of the 2000s when Art and his family—just kids hardly tall enough to carry a shovel—assisted install their family’s septic system alongside a experienced pro. Picture this: three youngsters knee-deep in Pennsylvania clay, discovering how soil absorption affects drainage while their buddies played Xbox. “We never just dig trenches,” Art told me last winter, warm coffee cup in hand. “We learned how ground whispers secrets. A patch of wetland vegetation here? That’s Mother Nature screaming ‘high water table.'”

https://www.instagram.com/septic_solutionsllc/

https://shorturl.fm/AEYoW

https://shorturl.fm/fmHtp

https://shorturl.fm/cfTzs

Scratch cards are such a fun, quick thrill! Seeing platforms like JILI333 offer diverse games-slots, live casino-is cool. Easy signup via the jili333 download apk makes it accessible, even with just 100 PHP to start! Definitely a modern take on instant wins.

https://shorturl.fm/y2fdL

https://shorturl.fm/TrG7P

https://shorturl.fm/3asLX

Interesting read! The focus on a seamless mobile experience, like with the xx777 casino app download apk, is key for Filipino players. Accessibility & security are huge-good to see that prioritized! 👍

Great article! It’s interesting how mobile gaming is evolving in the Philippines. Quick registration & easy PHP transactions, like with jiliok vip game, are key for player experience. Definitely a growing market! ✨

Here’s the dirty truth: the majority of septic companies just pump tanks. They’re like quick-fix salesmen at a disaster convention. But Septic Solutions? These guys are different. It all began back in the early 2000s when Art and his siblings—just kids barely tall enough to carry a shovel—helped install their family’s septic system alongside a experienced pro. Imagine this: three youngsters waist-deep in Pennsylvania clay, learning how soil porosity affects drainage while their friends played Xbox. “We did not just dig trenches,” Art shared with me last winter, steaming coffee cup in hand. “We understood how earth whispers truths. A patch of wetland vegetation here? That’s Mother Nature shouting ‘high water table.'”

https://www.bestprosintown.com/wa/marysville/product-air-heating-and-cooling-llc-/

Intuitive Click Hub – Everything feels carefully curated, site navigation is simple and enjoyable.

Let me share the dirty truth: nearly all septic companies just pump tanks. They act like band-aid salesmen at a chainsaw convention. But Septic Solutions? These guys are unique. It all originated back in the beginning of the 2000s when Art and his siblings—just kids scarcely tall enough to carry a shovel—aided install their family’s septic system alongside a weathered pro. Picture this: three youngsters knee-deep in Pennsylvania clay, discovering how soil absorption affects drainage while their friends played Xbox. “We didn’t just dig holes,” Art shared with me last winter, warm coffee cup in hand. “We understood how earth whispers mysteries. A patch of wetland vegetation here? That’s Mother Nature screaming ‘high water table.'”

https://arthuriyxw972.image-perth.org/how-product-air-heating-cooling-and-electric-services-in-marysville-wa-support-energy-efficiency

Global Essentials Store Hub – Excellent quality products, well-curated and easy to explore.

https://shorturl.fm/HcXwE

choice discovery – Emphasizes uncovering paths that align with current needs.

https://shorturl.fm/SNHrr

Thoughtful Experience Hub – Everything clearly arranged, making the browsing experience very satisfying.

possibility hub – Points toward organized exploration without overwhelm.

purpose discovery – Suggests guidance for uncovering meaningful goals.

Premium Essentials Central – Great assortment of products, very pleased with the quality and browsing experience.

purposeful progress – Reflects steady advancement guided by clear intention.

Sustainable Lifestyle Hub – Eco-friendly items presented clearly with easy navigation and responsible feel.

learn grow connect – Captures the blend of education and connection.

This is the dirty truth: nearly all septic companies just maintain tanks. They act like quick-fix salesmen at a demolition convention. But Septic Solutions? These guys are special. It all began back in the beginning of the 2000s when Art and his brothers—just kids hardly tall enough to carry a shovel—assisted install their family’s septic system alongside a experienced pro. Picture this: three kids waist-deep in Pennsylvania clay, understanding how soil absorption affects drainage while their friends played Xbox. “We never just dig trenches,” Art told me last winter, hot coffee cup in hand. “We discovered how ground whispers mysteries. A patch of cattails here? That’s Mother Nature yelling ‘high water table.'”

https://pixabay.com/users/53699776/

Curated Goods Hub – Items feel authentic and thoughtfully selected, very pleased with the recent purchase.

maximize potential – Highlights simple routines that enhance performance over time.

Mindful Marketplace Hub – Organized products with seamless browsing and intuitive interface.

collaborative thinking – Reinforces the importance of people shaping ideas together online.

Curated Finds Hub – Unique items arranged thoughtfully, providing a smooth browsing experience.

fresh start today – Reinforces the idea that today is perfect for beginning something new.

Refined Daily Picks – Orders arrived quickly, secure packaging, very happy with my purchase.

deep thinking – Suggests a space for exploring ideas that invite mindful reflection.

Ideas Made Simple – A clear and manageable way to explore creativity and innovation.

Discover Smarter Choices – A clean platform that guides users toward better options easily.

betterplanshub – Supports planning and implementing improved solutions.

renewyourday – Offers ways to refresh your mindset and start afresh.

create lasting value – A strong reminder that meaningful growth comes from patience and long-term thinking.

ideaunlimited – Encourages generating endless possibilities and creative inspiration.

Refined Essentials Picks Hub – Everything came fast with careful packaging and in perfect condition.

Explore New Ideas – A reliable space for discovering fresh thinking and modern perspectives each day.

problemresolver – Helps tackle issues with faster and more effective strategies.

This is the harsh truth: the majority of septic companies just maintain tanks. They’re like temporary salesmen at a disaster convention. But Septic Solutions? They are special. It all began back in the beginning of the 2000s when Art and his family—just kids barely tall enough to shoulder a shovel—assisted install their family’s septic system alongside a experienced pro. Picture this: three kids knee-deep in Pennsylvania clay, discovering how soil absorption affects drainage while their peers played Xbox. “We didn’t just dig holes,” Art told me last winter, hot coffee cup in hand. “We learned how earth whispers truths. A patch of cattails here? That’s Mother Nature screaming ‘high water table.'”

https://www.animenewsnetwork.com/bbs/phpBB2/profile.php?mode=viewprofile&u=1133543

Practical Learning Engine – Useful insights that help keep learning active and applied.

limitlessconcepts – Inspires discovering concepts that enhance creativity and innovation.

Freedom of Thought – Inspires innovative thinking in a way that’s fun and actionable.

Find Your Motivation – A simple destination for staying inspired and energized online.

todayfreshstart – Guides you to reset and embrace a new day with focus.

Better Decision Hub – A simple space to evaluate and select improved alternatives quickly.

momentumguide – Offers strategies to regain focus and continue moving forward.

Practical Learning Engine – Useful insights that help keep learning active and applied.

Innovative Freedom – Provides practical ways to explore ideas while maintaining creative freedom.

Influence Positive Outcomes – A straightforward concept designed to inspire better choices and results.

progresspathhub – Supports continuous improvement and learning every day.

Telecharger 1xbet 1xbet apk rdc

1xbet telechargement gratuit 1xbet apk

Growth Driven Network – A platform focused on linking development with practical outcomes.

Inspiration Every Day – A simple space for finding fresh, uplifting thoughts quickly.

https://shorturl.fm/1HSQe

freethinkingzone – Supports open-minded exploration of concepts and inspirations.

Project Starter Hub – Helps initiate tasks quickly while keeping daily progress on track.

momentumengine – Keeps your progress steady and your goals within reach.

https://shorturl.fm/QaFuv

Explore Smart Options – A focused experience aimed at keeping discovery organized.

Mental Edge Builder – Practical encouragement for strengthening focus and resilience over time.

powerwithin – Helps users recognize the strengths they already have.

createyourjourney – Motivates developing your narrative and achieving goals efficiently.

Unlock Growth Potential – A friendly site designed to help users explore new personal development strategies.

Sustainable Growth Ideas – Actionable insights that encourage growth with consistency and clarity.

focusonyourvision – Guides you to stay focused while shaping your goals.

Find Added Value – Easy-to-follow insights that turn small steps into meaningful gains.

Keep Advancing – A clean reminder to continue progressing in the right direction.

Next Step Hub – Encourages exploring better methods to overcome challenges and achieve goals.

potentialigniter – Sparks motivation to grow abilities and achieve targets.

Future Vision Hub – A clean concept focused on helping you see possibilities and plan strategically.

nextstepguide – Guides discovering the best path forward efficiently.

habitmastery – Encourages forming habits that improve daily productivity.

Creating Real Value – Well-explained concepts that feel relevant and easy to apply.

Unlock Your Creativity – A practical space built to stimulate fresh ideas and inventive solutions.

Stepwise Knowledge – Structured guidance for learning new concepts clearly and effectively.

Do And Learn – A friendly platform focused on learning efficiently through doing.

Intentional Growth – Carefully planned insights for steady, long-term advancement.

clarityzone – Provides insights for fast clarity and effective planning.

This is the ugly truth: most septic companies just service tanks. They are like temporary salesmen at a demolition convention. But Septic Solutions? They’re special. It all started back in the beginning of the 2000s when Art and his family—just kids scarcely tall enough to shoulder a shovel—assisted install their family’s septic system alongside a grizzled pro. Imagine this: three pre-teens knee-deep in Pennsylvania clay, understanding how soil porosity affects drainage while their friends played Xbox. “We never just dig holes,” Art shared with me last winter, hot coffee cup in hand. “We understood how earth whispers secrets. A patch of wetland vegetation here? That’s Mother Nature shouting ‘high water table.'”

https://files.fm/u/m6gcypjxnk

knowhowdaily – Helps acquire practical know-how for everyday tasks.

learnanduse – Helps learn new techniques and implement them efficiently.

Growth Discovery Hub – Helps you uncover chances to develop skills and advance in your career.

Think Differently Today – A clean environment for nurturing unique ideas and creative insights.

https://shorturl.fm/VL2dF

Learn Smartly – Simple yet effective ways to make learning focused and meaningful.

Discover Practical Ideas – A friendly space for exploring actionable and efficient methods.

growthengine – Helps maintain momentum while improving your skills effectively.

Build Value Daily – Practical steps to integrate value creation into everyday actions.

Connect To Success – A simple online concept linking development with real outcomes.

priorityplanner – Supports finding your main priorities and staying on track daily.

Creative Growth Space – Supportive content that encourages experimentation and personal expression.

boldthinking – Motivates daring ideas and fresh approaches to everyday challenges.

Explore Mental Growth – A clean site designed to inspire continuous mindset development.

Action & Progress – Practical advice to help convert ideas into tangible outcomes.

nextpathguide – Encourages taking actionable steps toward unexplored paths.

Modern Angles – Insightful ideas aimed at tackling problems with renewed clarity.

Get Clear Fast – A simple concept focused on fast understanding and purpose alignment.

<possibilityfocus – Encourages discovering opportunities and thinking creatively today.

First Step Hub – Inspires users to take the first step today toward their goals.

Momentum Matters – A focused concept encouraging steady action and positive change.

Focused Direction – A straightforward approach to regaining clarity and momentum.

sparkmotivation – Helps quickly discover motivational insights to energize your mind.

innovationstream – Offers constant inspiration for creative solutions.

Обман

Find Purpose Fast – A practical space offering quick ideas to gain clarity and direction without delay.

Global Ideas Network – Seamlessly connect with thinkers and innovators around the world.

futureinsights – Helps create forward-thinking strategies and actionable routines.

Discover Smart Ideas – A practical platform for locating creative, valuable thoughts to share.

pathclarity – Helps create a clear route to your desired outcomes.

clear positive steps – It helps simplify progress while staying motivated.

discoverabilities – Encourages discovering abilities for personal development.

begin effectively today – It encourages practical steps to start a journey and reach goals confidently.

discoverpossibilities – Helps uncover exciting options to pursue right away.

Here’s the ugly truth: nearly all septic companies just maintain tanks. They are like temporary salesmen at a disaster convention. But Septic Solutions? They are different. It all began back in the beginning of the 2000s when Art and his siblings—just kids barely tall enough to shoulder a shovel—assisted install their family’s septic system alongside a weathered pro. Picture this: three kids waist-deep in Pennsylvania clay, discovering how soil permeability affects drainage while their friends played Xbox. “We never just dig trenches,” Art shared with me last winter, hot coffee cup in hand. “We understood how earth whispers secrets. A patch of wetland vegetation here? That’s Mother Nature screaming ‘high water table.'”